Coated peanut production line is widely used in the process of coated peanuts, coated cashew, coated macadamia, coated green bean, coated broad bean, coated sunflower seeds etc.

Manufacturer of automatic coated peanut production line

Whether it’s fish skin peanuts, sugar skin peanuts, or multi flavored peanuts, wrapped peanut processing solutions can allow you to stably control the flavor and taste of the finished product. From wrapping to baking or frying, whether it’s small, medium or large operations – our customized solutions will be tailored to your needs.

Working flow of automatic coated peanut production line:

Powder and syrup mixing—Coating—Roasting—Seasoning—Drying—Cooling

we can customize the capacity from 100kg/h-1000kg/h according to your requirements.

Also we can support you with formula of each processing step and help you to finish the final products.

The specific process flow of this solution is as follows: the graded peanuts are first roasted to 5-6 degrees of maturity, cooled, and then wrapped by a coating machine before being transported to a screening machine to screen out excess dry powder. Drying the syrup inside the dried peanuts to prevent them from sticking to each other. Dried peanut preforms are baked in batches using a swing oven, then seasoned with an octagonal seasoning machine and concentrated in a cooling zone for pre packaging cooling.

This scheme significantly improves efficiency, with uniform thickness of the coating layer, bright and uniform color, high yield rate, simple operation, strong reliability, and wide applicability.

Brief introduction:

Coated nuts production line is widely used in the process of coated peanuts, coated cashew, coated macadamia,

coated green bean, coated broad bean, coated sunflower seeds etc.

Material products Final products

| Peanut |  | Fish skin peanut Coated peanut |    |

| Cashew |  | Coated Cashew |    |

Macadamia |  | Coated Macadamia kernel |    |

| Sunflower seeds |  | Coated Sunflower seeds |    |

| Green bean |  | Coated Green bean |    |

| Broad bean (half kernel) |  | Coated Broad bean half kernel |    |

Main equipment introduction:

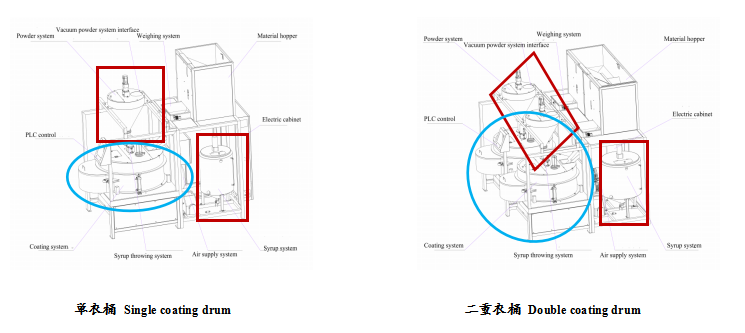

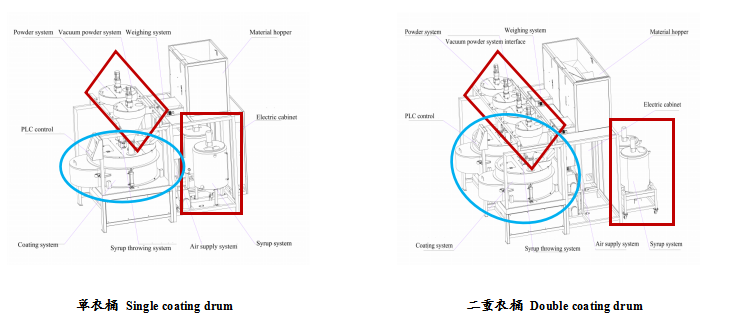

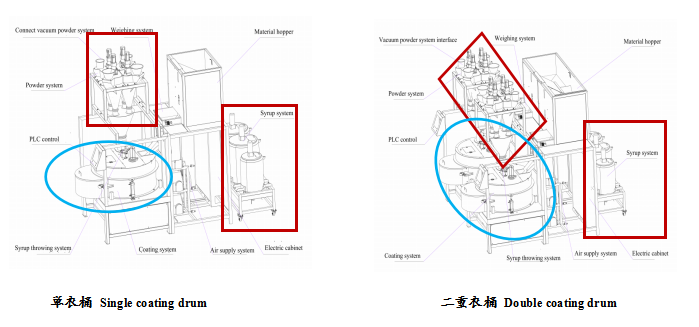

1.Automatic Coating Machine

| Suitable for coating and powder processing of nut seed products such as peanuts, sunflower seeds, fava beans, almond, cashew, macadamia, etc. PLC automation control, automatic replenishment of raw materials, powders, and syrup materials, and changes in addition parameters and speed during the coating process according to the process, meeting the process requirements of various products. The enclosed structure improves the problem of dust pollution in traditional processing. One click intelligent operation is highly automated, greatly reducing labor intensity and reliance on worker coating technology; Ensure that the quality and uniformity of coating are no longer affected by human factors; Achieved automated production with one person with whole line, and high output and quality. |

| According to different production and formula requirements, single and double coating barrels can be configured, and multiple models of single powder, single liquid, double powder, and multiple liquid can be customized |    |

| 1 powder tank 1 syrup tank |  | |

| 2 powder tank 2 syrup tank |  | |

| 4 powder tank 3 syrup tank |  |

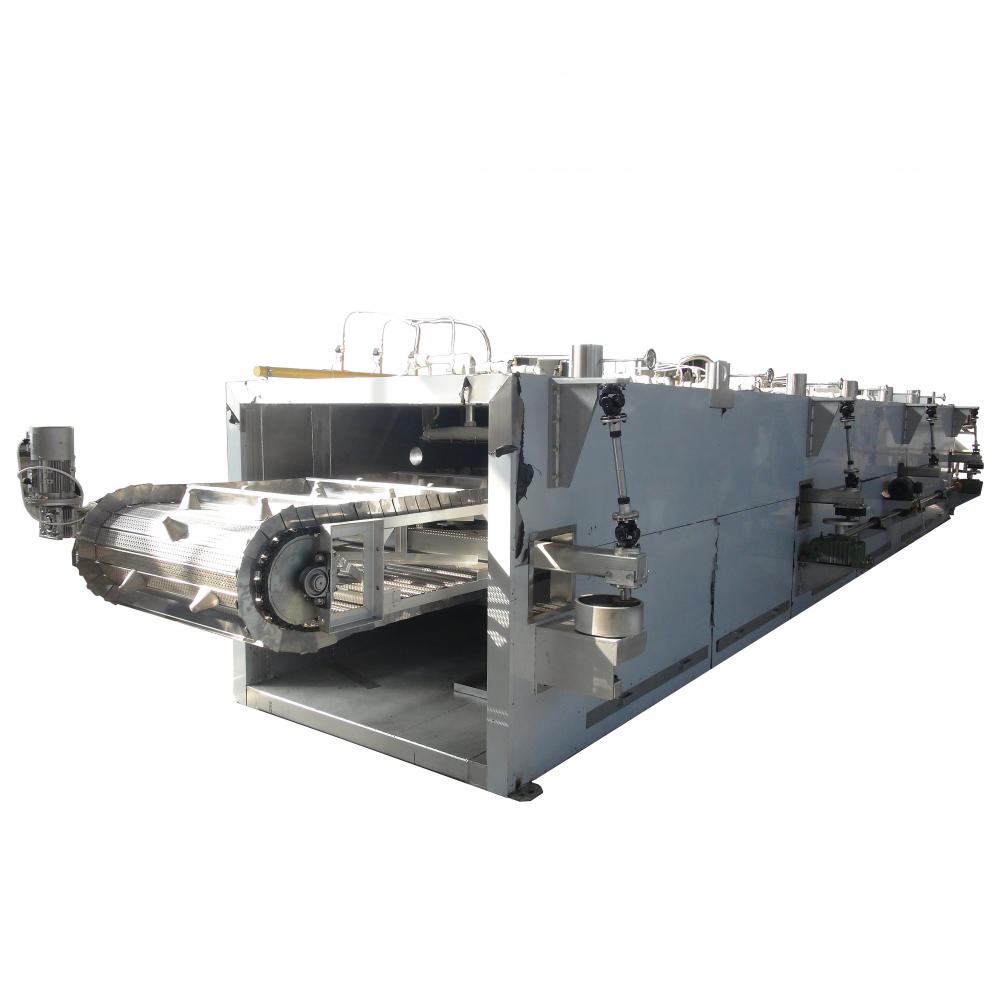

2.Combination of swing roasters

| Swing Roaster / Flat & Rotary Roaster is also called Coated Peanut Roaster /Japanese peanut roaster , it is designed to roast flavored coated peanut, sunflower seeds, cashew nut, almonds, walnuts, hazelnut, cashew, macadamia seeds etc. |

| Model | Picture | Power (kw) | Capacity (kg/h) | Gas consumption (m³/h) | Weight (kg) | Dimension (mm) |

| PDK-60 |  | 0.75 | 30-50 | 5-8 | 750 | 2800*2400*1900 |

| PDK-90 |  | 1.5 | 50-120 | 10-15 | 2900 | 4200*3840*2300 |

| PDK-1200 |  | 4.75 | 150-300 | 40-50 | 7500 | 12300*2550*2080 |