The Degradable Automatic Square Bottom Paper Bag Making Machine(120-260 pcs/min) controls by PC programmable servo motor through the human-machine touch screen interface, which from the roll paper to the printing, side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. It is an ideal machine for producing food bag, shopping handles bag.

high speed, quickly replace the paper bag specifications, more wide range adjusting.

ink Ceramic Anilox roller, high speed dot rate, screen printed layered, stronger.

Accurate color tracking system, color errors automatically shut down.

Degradable automatic square bottom paper bag making machine

This machine is used to make paper bags automatically by using primary color paper or printing web paper, such as kraft paper, food paper and so on. It is completed by automatic center gluing, printing tracking, raw material canning, fixed length cutting, bottom indentation, bottom folding, bottom gluing, bag bottom forming and finished bag finishing. This machine adopts motion controller, servo motor programming, easy to operate, efficient production, stable operation, is the production of various sizes of square bottom paper bags, bread bags, leisure food bags, shopping bags and other environmental protection paper bag special paper bag machine.

This machine is used to make paper bags automatically by using primary color paper or printing web paper, such as kraft paper, food paper and so on. It is completed by automatic center gluing, printing tracking, raw material canning, fixed length cutting, bottom indentation, bottom folding, bottom gluing, bag bottom forming and finished bag finishing.

This machine adopts motion controller, servo motor programming, easy to operate, efficient production, stable operation, is the production of various sizes of square bottom paper bags, bread bags, leisure food bags, shopping bags and other environmental protection paper bag special paper bag machine.

Types of square paper bag machines

Fully Automatic Sqaure Bottom Paper Bag Machine With Handle Machine Inline

Fully-automatic paper bag machine is used to produce hand-held paper bags by using roll paper as raw material, combined with hand-held paper pieces and paper ropes. The machine adopts PLC and motion controller, servo drive control system, intelligent operation interface, high production speed, high efficiency, is the ideal equipment for the production of food, cosmetics, wine, gifts and clothing bags.

The production process: drum feeding, stick handle, tube forming, cutting, bottom indentation, bottom gluing, bag bottom forming and output.

CHARACTERISTIC

01 The forming template adopts symmetrical adjustable double- template structure (proprietary technology), so that users of different sizes of paper bags no longer need to change the template, which can effectively reduce the time of paper bag size adjustment and increase the machine capacity.

02 The special design greatly improves the bag-making range of the machine, which can meet the customer’s demand of producing extra-large hand-held paper bags.

03 The electronic control system from Japan is adopted to ensure stable and high-speed operation

04 Material loading adopts hydraulic automatic lifting structure, with automatic tension control.

05 material loading adopts ARISE EPC system, reduce material alignment time.

PARAMETER 参数

| model | ZXFD-180 | ZXFD-330 | ZXFD-460 |

| Roll paper diameter | 1300mm | 1300mm | 1300mm |

| Roll paper inner diameter | Φ76mm | Φ76mm | Φ76mm |

| bag bottom width | 50-100mm | 60-180mm | 100-200mm(80-180mm) |

| Roll paper width | 285-620mm | 425-1050mm | 625-1350mm |

| bag width | 80-190mm | 140-330mm | 220-460mm |

| bag width(Automatic) | 120-190mm | 200-330mm | 250-460mm |

| Roll paper cutting length | 190-370mm | 260-530mm | 260-530mm |

| Rollpapercuttinglength(Automatic) | 190-270mm | 260-430mm | 260-430mm |

| Paper gram weight | 50-130g/m2 | 60-150g/m2 | 80-150g/m2 |

| Papergramweight( Automatic) | 70-130g/m2 | 80-150g/m2 | 80-150g/m2 |

| Bag making speed | 30-200pcs/min | 30-180pcs/min | 30-150pcs/min |

| Bagmakingspeed (Automatic) | 30-150pcs/min | 30-150pcs/min | 30-120pcs/min |

| Total Motor power | 13kw | 14kw | 15kw |

| TotalMotorpower (Automatic) | 25kw | 28kw | 30kw |

| Machine weight | 5000kg | 6500kg | 7500kg |

| Machine weight (Automatic) | 13000kg | 15000kg | 16500kg |

| Dimension | 9.2*1.6*1.75m | 11*2.6*1.8m | 11*3*1.8m |

| Dimension(Automatic) | 13*7*2.6m | 15*8*2.6m | 15*8*2.6m |

| baglengthofMaxbottom(automatic) | 200mm | 320mm | 310mm(320mm) |

| baglengthofminimumbottom(automatic) | 230mm | 380mm | 360mm(370mm) |

| Flat rope technical parameter | ZXFD-180 | ZXFD-330 | ZXFD-460 |

| Flat rope spacing | 47.6mm | 76mm | 95mm |

| Flat rope width | 12mm | 12mm | 12mm |

| Flat rope height | 100mm | 100mm | 100mm |

| Paster width | 50mm | 50mm | 50mm |

| Paster length | 95mm | 152mm | 190mm |

| Unwinding paster length | 100mm | 100mm | 100mm |

| Paper gram per square meter | 120g/m2 | 120g/m2 | 120g/m2 |

| Handle paper roll diameter | 1000mm | 1000mm | 1000mm |

| Roundropetechnicalparameter | ZXFD-180 | ZXFD-330 | ZXFD-460 |

| Handle paster length | 95mm | 152mm | 190mm |

| Handle paster width | 50mm | 50mm | 50mm |

| Paper rope spacing | 47.6mm | 76mm | 95mm |

| Handle paper rope diameter | 3-5mm | 3-5mm | 3-5mm |

| Handle poster paper roll width | 100mm | 100mm | 100mm |

| Handle paper roll width | 1000mm | 1000mm | 1000mm |

| Handle paster gram per square meter | 80-135g/m2 | 80-135g/m2 | 80-135g/m2 |

SQUARE BOTTOM PAPER BAG MACHINE

the machine can produce the square bottom paper bag in conjunction with overseas advanced technology. The machine has many advantages such as high speed ,high productive effciency and wide-range adjustment. Automatic raw material feeding,automatic errors correct system and tension control,all these operational procedures are controlled by PLC. This is ideal equipment for producing varies kinds of paper bags such as food paper bags ; cosmetics handle paper bags. ect .

Automatic square bottom paper bag making machine Characteristics :

- Equipped with servo system with photocell for correction,tracking the printed material accuracy .

- The electric control system promotes high speed,high precision motion control and production line. It detects automatically effect of integration and optical fiber .

- The touch screen display simplifies machine operation.

- The glue applicator system helos glue to move automatically as machine running .

- Automatic fault detector and self diagnosis system reduce the chance to damage machine

| Model | RZFD-190 |

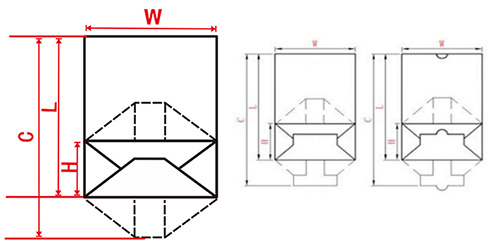

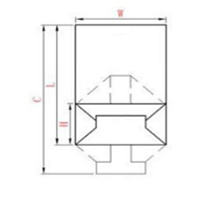

| Cutting length C | 190-370mm |

| Paper bag width W | 80-190mm |

| Paper bag bottom width H | 50-105mm |

| Paper thickness | 50-130g/m2 |

| Paper bag speed | 30-200 pcs/min |

| Paper roll Maximum width | 620mm |

| Roll paper diameter | 1200mm |

| Machine power | 3phase 4line 380V 12kw |

| Machine weight | 5800 kg |

| Machine size(mm) | 8200x3200x1900 |

| Bottom types |  |

Square Bottom Paper Bag Making Machine With Color Printing Machine

Ø Roll Feeding Square Bottom Paper Bag Making Machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various specifications of paper bags. This machine has advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bags, shopping bags.

Ø In addition, the machine adds the function of hand – holing, making the products more competitive and diversified.

Main Technical Parameter:

| Model | HWFD220 | HWFD280 | HWFD330 | HWFD450 | HWFD450B | HWFD540 |

| Bag Tube Length(mm) | 190-370 | 270-530 | 270-530 | 285-530 | 420-760 | 420-760 |

| Bag Length(mm) | 150-320 | 225-470 | 225-470 | 225-470 | 320-680 | 320-680 |

| Bag Width(mm) | 80-220 | 120-280 | 150-330 | 220-450 | 200-450 | 250-540 |

| Bottom Width(mm) | 50-120 | 60-160 | 60-180 | 80-220 | 80-220 | 120-260 |

| Paper Thickness(g/㎡) | 50-130 | 60-160 | 60-160 | 80-160 | 80-160 | 90-160 |

| Paper Roll Diameter(mm) | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 |

| Paper Roll Width(mm) | 290-670 | 385-910 | 445-1050 | 630-1330 | 590-1330 | 770-1640 |

| Bag Making Speed(pcs/min) | 30-200 | 30-180 | 30-160 | 30-150 | 30-120 | 30-120 |

| Power Supply(kw) | 10 | 12 | 12 | 12 | 16.5 | 16.5 |

| Machine Weight(kgs) | 5500 | 7000 | 8000 | 9000 | 10000 | 12000 |

| Machine Dimension(mm) | 8000X2980X1800 | 9700X2980X1900 | 9800X3050X1900 | 10200X3150X2200 | 11265X3400X2200 | 11250X3400X2160 |

SQUARE BOTTOM PAPER BAG MACHINE WITH DIE CUT HANDLE

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

| Model | RZFD-450D |  |

| Cutting length | 270-530mm | |

| Die cut Handle | 35mm*85m | |

| Bag width | 220-450mm | |

| Bottom width | 90-180 mm |  |

| Paper thickness | 70-140g/m2 | |

| Paper thickness(Patch bag) | 80-140g/m2 |  |

| Reinforce piece thickness | 100-150g/m² or Poly film: 0.04-0.07mm | |

| Width of reinforce piece | 100-150mm |  |

| Length of reinforce piece | 70-120mm | |

| Machine Speed | 30-160pcs/min | |

| Paper bag speed | 30-140pcs/min | |

| Patch Bag speed | 30-130pcs/min |  |

Maximum Paper roll width | 1290mm | |

| Maximum Roll paper diameter | 1200mm | |

| Machine power | 3phase 4line 380V 40 KW | |

| Machine size and weight | 14000*3800*2200 9000kgs |

Automatic High Speed Food Paper Bag Making Machine

Charaterictics:

1.Suited for 40-80gsm paper.

2.Controls bag length through the human-machine interface.

3.PLC system for calculating parameters.

4. Equipped with an accurate photocell system.

Bottom Paper Bag Making Machine ProductMain technical variables:

| MODEL: | JD400 | JD650 | JD850 |

| bag weight: | 40-80g/m2 | 40-80g/m2 | 40-80g/m2 |

| tube length: | 160-420mm | 220-650mm | 220-850mm |

| bag width: | 70-260mm | 80-300mm | 80-350mm |

| speed: | 60-400bags/min | 60-400bags/min | 60-400bags/min |

| weight: | 3000kg | 4200kg | 5200kg |

| max paper roll width: | 260-720mm | 260-840mm | 260-960mm |

| power: | 10kw | 10kw | 10kw |

| insert size: | 20-120mm | 20-120mm | 20-120mm |

| machine size (L*W*H): | 4500x2100x1900mm | 5000*2100*2000 | 5300*2100*2000 |

Square bottom paper bag making machine with window

This machine can use the rolling paper, which is made of primary color paper or printed to produce square bottom paper bag to one time. This machine can produce various of paper bags, with fast speed, high production efficiency, is an ideal equipment for paper bag production.

This machine is composed of rlling paper feed (hydraulic feeding, automatic deviation correction, constant tension), side glue, printing paper electric eye tracking, original paper into roll, fixed length traction cutting, bag bottom indentation opening bottom, bag bottom gluing folding forming and bag output. The whole machine is controlled by the computer central control system, the touch screen display, and the servo motor controls the length of the paper bag.

According to customer needs, two/ four color printing machine, Paper bag windowing device and paper bag hand holing device or paper handle bar device can be customized.

Paper bag machine parameter:

| Model | HWFD220 | HWFD280 | HWFD330 | HWFD450 | HWFD450B | HWFD540 |

| Bag Tube Length(mm) | 190-370 | 270-530 | 270-530 | 285-530 | 420-760 | 420-760 |

| Bag Length(mm) | 150-320 | 225-470 | 225-470 | 225-470 | 320-680 | 320-680 |

| Bag Width(mm) | 80-220 | 120-280 | 150-330 | 220-450 | 200-450 | 250-540 |

| Bottom Width(mm) | 50-120 | 60-160 | 60-180 | 80-220 | 80-220 | 120-260 |

| Paper Thickness(g/㎡) | 50-130 | 60-160 | 60-160 | 80-160 | 80-160 | 90-160 |

| Paper Roll Diameter(mm) | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 | ᴓ1300 |

| Paper Roll Width(mm) | 290-670 | 385-910 | 445-1050 | 630-1330 | 590-1330 | 770-1640 |

| Bag Making Speed(pcs/min) | 30-200 | 30-180 | 30-160 | 30-150 | 30-120 | 30-120 |

| Power Supply(kw) | 10 | 12 | 12 | 12 | 16.5 | 16.5 |

| Machine Weight(kgs) | 5500 | 7000 | 8000 | 9000 | 10000 | 12000 |

| Machine Dimension(mm) | 8000X2980X1800 | 9700X2980X1900 | 9800X3050X1900 | 10200X3150X2200 | 11265X3400X2200 | 11250X3400X2160 |

PRODUCTS FEATURE:

This machine can use the rolling paper, which is made of primary color paper or printed to produce square bottom paper bag to one time. This machine can produce various of paper bags, with fast speed, high production efficiency, is an ideal equipment for paper bag production.

The machine operation more convenient, more efficient, more stable is in the production of a variety of different paper bags, fenestration bread bags, leisure food bag, bag of bread, dried fruit bags and so on environmental paper bag paper bag machine equipment. According to customer needs, two/ four-color printing machine, Paper bag windowing device and paper bag hand holing device can be customized.